The SZ-S100 ship crane load moment indicator, produced by SeeZol Technology, is a critical safety device installed on ship cranes to prevent accidents such as capsizing or structural damage due to overloading or improper operation.

It serves as the “safety brain” of ship crane operations—through real-time moment monitoring and calculation, overload warnings and robust protection, traceable data recording, and adaptive sea conditions for stable operation. It not only prevents accidents caused by human error but also helps improve operational efficiency, making it an indispensable and mandatory safety device for ship cranes.

The SZ-S100 ship crane load moment indicator operates based on the principle of moment balance, which states that a crane’s lifting moment must not exceed its rated moment. Lifting moment is determined by the load capacity and boom reach. The load moment indicator uses sensors to monitor crane parameters such as the load capacity, boom reach, and boom angle in real time, and calculates the current lifting moment. When the lifting moment approaches or exceeds the rated moment, the load moment indicator issues an alarm and automatically cuts off dangerous operations.

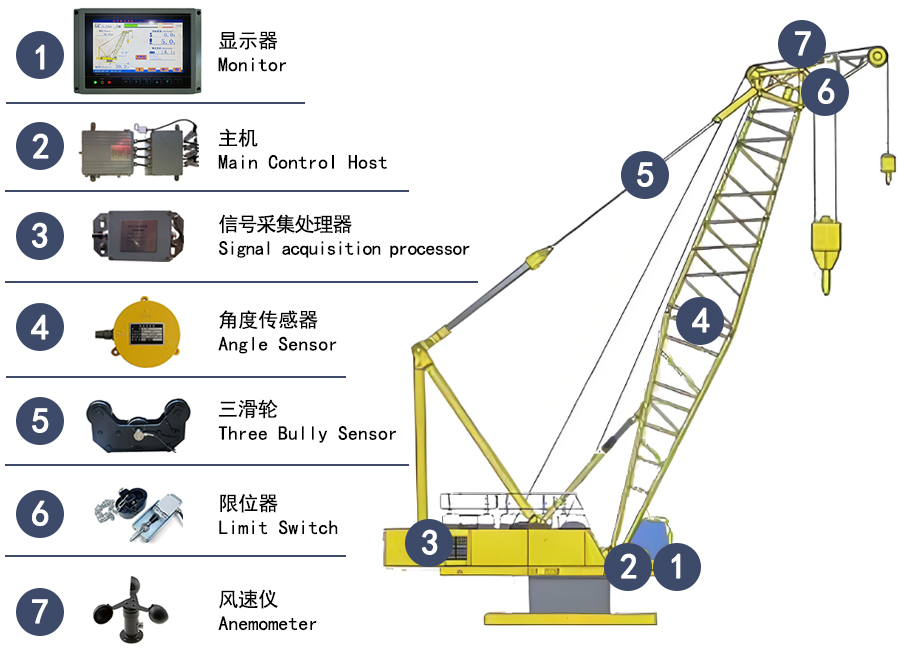

The SZ-S100 ship crane load moment indicator primarily consists of sensors, a signal acquisition and processing module, a microprocessor, a display and operation unit, an alarm and control unit, and a power supply module. These components work together to ensure safe and reliable ship crane operations.

Weight sensor often use three-pulley sensor to directly measure wire rope tension. This type of sensor offers high accuracy and adapts to the complex load conditions of ship’s cranes. Furthermore, due to the wide range of boom angles and amplitudes during ship crane operation, the SZ-S100 utilizes a highly accurate and reliable angle sensor.

Furthermore, ship cranes are significantly affected by wind speed. During land-based operations, wind primarily affects the swaying of loads. However, due to the floating nature of ship cranes, wind speed can interfere with moment calculation, equipment posture, and operational control, potentially even causing the load moment indicator’s protective functions to malfunction. Therefore, the SZ-S100 ship crane load moment indicator is equipped with a wind speed sensor. Incorporating wind speed monitoring into the pre-process and combining it with the load moment indicator’s dynamic compensation function ensures a balance between safety and efficiency.

Compared to land-based cranes, ship cranes tilt with the swaying of wind and waves. Therefore, it is recommended to equip them with a hull inclination sensor to detect the hull’s inclination angle. This factor can be factored into moment calculations, increasing moment accuracy and ensuring safer ship crane operations.

Unlike land-based cranes, ship cranes often operate in environments characterized by high humidity, salt spray, strong vibration, and frequent winds and waves. Therefore, the load moment indicator hardware design must incorporate targeted protective features. To adapt to harsh ship operating conditions, the SZ-S100 ship crane load moment indicator features a sealed housing that is waterproof and salt spray-resistant. The internal circuitry is resistant to vibration and electromagnetic interference, preventing equipment failures caused by seawater corrosion and hull vibration. It also supports a wide input voltage (compatible with ship power systems) and features overvoltage and overcurrent protection, ensuring stable operation and uninterrupted safety protection even during fluctuations in the ship’s power supply.

SeeZol Technology specializes in safety monitoring systems for construction machinery. Its series of load moment indicators, weighing scales, and supporting systems are custom-developed and widely used in various types of construction machinery, ensuring safe and efficient production for enterprises.