In a crane load moment indicator system, the weight sensor is a core component. Based on ease of installation and accuracy, hydraulic pressure sensors, side-pressure sensors, and three-pulley sensors are commonly chosen.

I. Differences in Core Working Principles

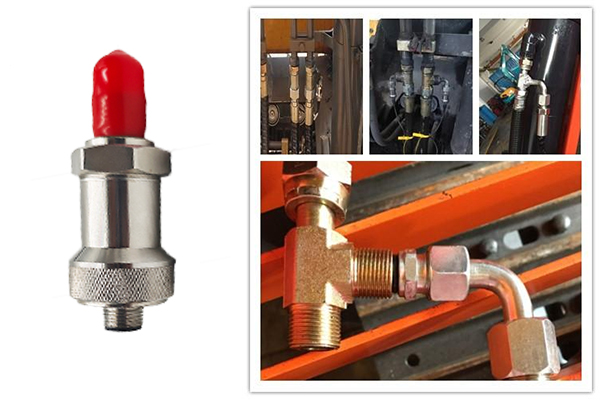

Hydraulic Pressure Sensor: Requires connection to a hydraulic line, relies on system sealing, and is suitable for hydraulically driven cranes. It indirectly calculates the weight of the load by detecting the hydraulic system pressure.

Side-Pressure Sensor: The sensor is fixed to the fixed end of the wire rope using U-bolts. It is suitable for low-speed scenarios where there is no relative movement of the wire rope. The wire rope tension is transmitted to an elastic body through a guide wheel, and strain gauges detect deformation to measure force.

Three-Pulley Sensor: The wire rope passes through three pulleys to form a V-shaped angle. The lateral force is detected by strain gauges detecting the deformation of the pulley bracket. It is suitable for high-speed moving or swinging wire ropes, directly measuring force by utilizing the shear force of the wire rope tension reaction on the pulleys.

II. Key Performance Comparison

| Comparison Dimensions | Hydraulic Pressure Sensor | Side-Pressure Sensor | Three-Pulley Sensor |

| Measurement Accuracy | ±0.25%~±0.5% FS (with temperature compensation) | ±0.3%~±0.5% FS (dual-hole shear beam structure) | ±0.2%~±0.5% FS (dynamic response advantage) |

| Dynamic Response | Response Time <1ms (rapid adjustment of hydraulic system) | Response Frequency 10Hz~1kHz (standard) | Response Frequency 10kHz (suitable for emergency start/stop) |

| Temperature Range | -40℃~125℃ (industrial grade) | -20℃~65℃ (standard model) | -20℃~60℃ (requires additional high-temperature customization) |

| Vibration Resistance | Shock Resistance 50g (e.g., HDA4745 series) | U-bolt tightness needs regular check | structural design resists wire rope sway (movable base) |

| Installation | Connect to the hydraulic circuit via flange | directly clamp the wire rope | insert into the wire rope path |

| Maintenance | Check hydraulic oil cleanliness quarterly (ISO) (Grade ≤18/15), replace filter element annually | check U-bolt torque every six months (torque wrench recommended), calibrate zero-point drift annually | lubricate pulley bearings quarterly (high-temperature grease recommended), and check wire rope wear every six months |

III. Selection Recommendations

Selection by Crane Type:

Hydraulic Drive Type (e.g., truck cranes, crawler cranes): Prioritize hydraulic pressure sensors, which directly utilize hydraulic system pressure, offering low cost and strong adaptability.

Pin-Connection Type (e.g., gantry crane fixed spreaders): Prioritize pressure-side sensors, which are easy to install and do not damage the wire rope.

Wire Rope Moving Type (e.g., port gantry cranes, cable cranes): Prioritize three-pulley sensors, offering fast dynamic response and resistance to swaying.

Selection by Environmental Conditions:

High Temperature Environment (>80℃): Hydraulic pressure sensors (e.g., HDA7746 series) or high-temperature resistant three-pulley sensors (customization required).

Dusty/Humid Environment: Three-pulley sensors (IP67 protection) or sealed pressure-side sensors.

High Vibration Environment: Hydraulic pressure sensors (50g shock resistance) or three-pulley sensors (movable base).

Selection by Cost and Maintenance Needs:

Limited Budget and Limited Maintenance Capabilities: Pressure-side sensors (low initial cost + simple maintenance).

For high precision and low maintenance: Three-pulley sensors (dynamic response + no periodic calibration required).

For hydraulic systems with existing redundant monitoring: Oil pressure sensors as an auxiliary solution.

IV. Summary

Hydraulic Pressure Sensor: Suitable for hydraulically driven cranes, exhibiting excellent performance in high-temperature environments, but complex maintenance and weak dynamic response.

Side-Pressure Sensor: Suitable for low-speed, fixed-end scenarios, simple installation and lowest cost, but limited anti-interference capabilities.

Three-Pulley Sensor: Suitable for high-speed, dynamic scenarios, offering balanced overall performance and moderate maintenance costs, making them the preferred choice for general applications.

V. Final Recommendations

Based on crane type, environmental conditions, and maintenance capabilities, prioritize three-pulley sensors (general applications) or side-pressure sensors (low-cost retrofit). Hydraulic drive equipment can be combined with oil pressure sensors for auxiliary monitoring. For long-term operation, it is recommended to implement remote sensor status diagnostics through an IoT platform to further reduce maintenance costs.