I. Upgrade Background

Load moment indicators are core safety devices for construction machinery (tower cranes, hoists, etc.), requiring real-time collection of load moment, angle, and other data to ensure load safety. Addressing the limitations of traditional wired transmission in mobile device wiring and complex environments, SEEZOL Technology has developed a wireless sensor transmission solution that retains wired interfaces for dual-mode compatibility, building a flexible and safe control system.

II. Core Advantages of the Wireless Transmission Solution

Based on the SEEZOL industrial-grade wireless technology architecture, the solution offers five key advantages:

1. High Flexibility and Scenario Adaptability: Eliminating cable constraints, this solution solves cable entanglement and wear issues in tower crane slewing mechanisms and telescopic boom cranes, reducing installation time by 60%, and is suitable for complex wiring scenarios such as steel structure factories and mountainous areas.

2. Strong Interference Resistance and Stable Transmission: Utilizing the LoRaWAN 433MHz frequency band with Frequency Hopping Spread Spectrum (FHSS) technology, combined with a forward error correction (FEC) algorithm, it resists electromagnetic interference and metal obstruction, achieving a bit error rate as low as 10⁻⁷, surpassing the industry average.

3. Efficient Maintenance and Cost Optimization: Eliminating the need for regular inspections of cable connectors and routing, maintenance workload is reduced by 70%, costs by 40%, and equipment downtime due to transmission failures is significantly reduced.

4. Wide Temperature and Environmental Adaptability: The wireless modules (SZ-WM100/SZ-WR200) feature IP67 protection and an operating temperature range of – Operating temperature: 40°C to 85°C, resistant to high dust levels and 95% non-condensing relative humidity, suitable for diverse operating conditions.

5. Low latency and security: Transmission latency is ≤50ms, meeting real-time alert requirements. Supports AES-128 end-to-end encryption and complies with GB/T 28526-2012 data security requirements.

III. Wireless Transmission Technology Principle

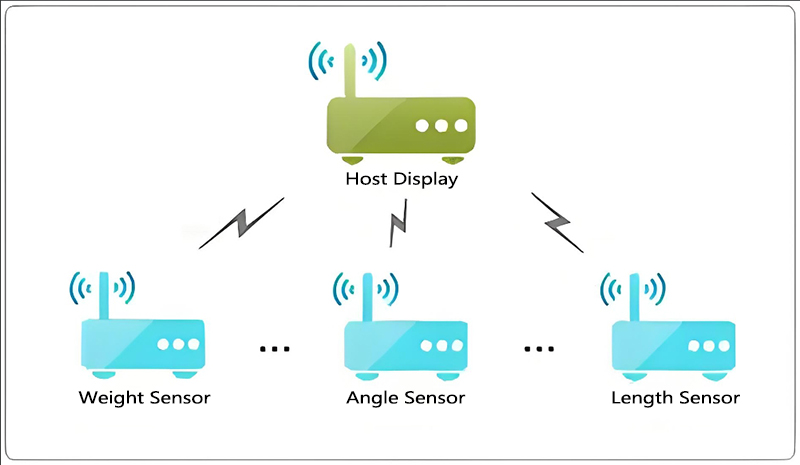

The solution uses a layered architecture to ensure performance:

1. Protocol and Hardware: The LoRaWAN protocol is used. The SZ-WM100 sensor module converts the 4-20mA analog signal into a digital signal using a 16-bit ADC chip. The signal is then transmitted using GFSK modulation (power ≤ 20dBm) via the CC1310 radio chip.

2. Signal Coverage and Reception: The transmission distance is 300 meters in open environments and ≥ 50 meters in complex industrial environments. The SZ-WR200 receiver module demodulates the signal and transmits it to the controller via the RS485 interface, forming a complete link.

3. Intelligent Expansion: The system supports OTA remote firmware upgrades and can be connected to the SEEZOL Industrial IoT platform in the future, enabling data linkage and predictive maintenance.

IV. Dual-Mode Compatible Design

The solution retains the RS485 wired interface, achieving complementary advantages:

1. Fixed equipment scenarios (gantry and bridge cranes): The wired solution offers lower hardware costs and is suitable for long-term stable operation.

2. Extreme interference scenarios (ultra-high voltage electromagnetic environments): Switch to wired mode, leveraging the anti-interference properties of shielded twisted-pair cable to ensure uninterrupted safety control.

V. Summary

The SEEZOL wireless load moment indicator solution focuses on flexibility, stability, and affordability, overcoming the pain points of wired solutions with a dual-mode design that accommodates specialized scenarios. This upgrade not only expands the torque limiter’s application range and improves reliability, but also demonstrates SEEZOL’s commitment to matching customer needs with technological innovation, providing a superior solution for construction machinery safety control.