Technical Aspect

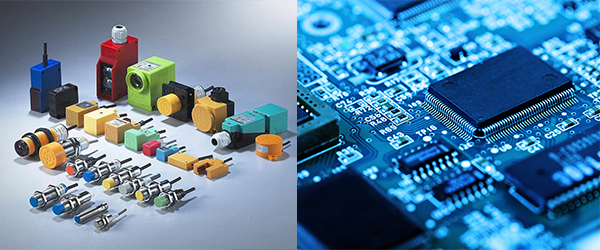

Multi-sensor Fusion: Angle sensors, oil pressure sensors, etc. are adopted to obtain data such as boom angle and hydraulic pressure, enabling accurate calculation of load torque.

Intelligent Control Upgrade: Fuzzy control and neural network algorithms are utilized to integrate multi-source data, precisely evaluate the working state, and achieve real-time and accurate control.

Enhanced Data Processing: A large amount of data is collected in real-time. Through analysis, it can determine overload and warn of potential risks, assisting in operation and maintenance.

Product Aspect

Diverse and Complementary Types: Mechanical type is simple, reliable and has low cost but poor accuracy; electronic type has high accuracy and fast response; hydraulic type has large torque and is suitable for large heavy-duty excavators.

Continuous Function Expansion: In addition to basic torque limiting and overload alarm functions, it can display the working state, have a fault diagnosis function, and some support remote monitoring.

Development Trends

Intelligentization: Combine artificial intelligence and big data technologies to realize intelligent control and optimization of the load torque limiter.

Integration: Integrate the load torque limiter with other safety systems (such as anti-collision systems, remote monitoring systems, etc.) to form a comprehensive safety solution.

IoT-enabled: Enterprises possess their own customized IoT systems and realize function customization according to their own industry needs.

Lightweight and Miniaturization: Through new materials and new processes, reduce the weight and volume of the load moment indicator to improve its applicability.