Mobile crane load moment limiter also known as crane Load Moment Indicator (LMI) or crane Safe Load Indicator (SLI) provides the crane operator with effective operation information, which enables the crane to be used effectively in the range of its design parameters.

Recently, during the construction of the landmark super-high-rise office building “Zhuoyue Century Center” in Qianhai, Shenzhen, China Construction Eighth Engineering Division introduced the SeeZol – LMI – Pro load moment indicator developed by Sizhuo Technology. This system successfully addressed the challenges of safe lifting operations in a complex construction environment. The building stands at a height of 380 meters and has a total construction area of 280,000 square meters. The construction site is adjacent to the main Shennan Avenue, with a complex network of underground subway lines and pipelines. Affected by the South China Sea monsoon, the area experiences over 40 days of winds exceeding level 6 each year, posing stringent requirements for the safety and precision of truck crane operations.

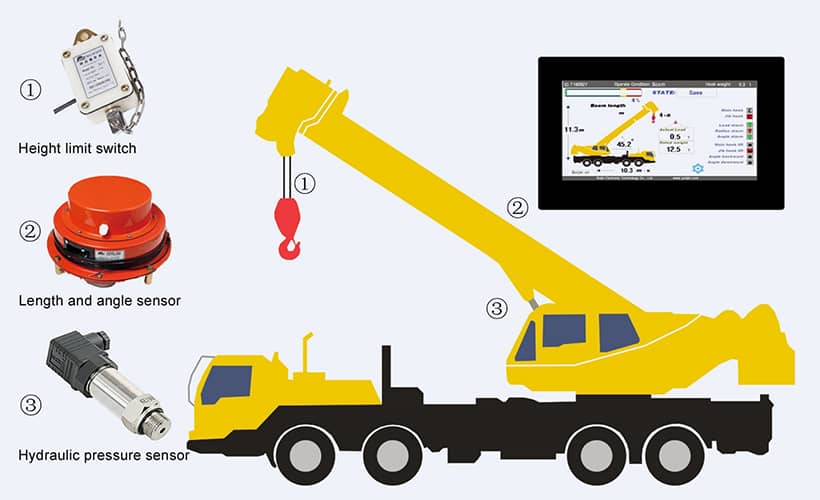

During the critical stage of the main structure construction, a 50-ton truck crane equipped with the SeeZol Technology system undertook core lifting tasks. On an afternoon of a recent working day, the Shenzhen Meteorological Bureau issued a blue gale warning. Strong winds from the sea increased the wind force at the construction site to level 5. At that time, the crane operator was tasked with lifting a precast concrete exterior wall panel weighing 20 tons, with dimensions of 6 meters by 3 meters, to the 12th floor (approximately 40 meters high). When the crane boom extended to 25 meters and the elevation angle reached 40°, the SeeZol – LMI – Pro system collected data from weight, angle, and length sensors simultaneously at a high sampling rate of 10 times per second.

Through millisecond-level calculations by the built-in AI-powered intelligent chip, it determined that the current load moment had reached 89% of the rated value and immediately activated a three-level warning mechanism: the high-brightness yellow warning light in the cab flashed rapidly, a low-frequency buzzer sounded continuously at 105 decibels, and a red dynamic pop-up window on the 7-inch high-definition touch screen displayed the message “Moment approaching critical value! Adjust elevation angle/radius recommended.” Meanwhile, a three-dimensional moment risk heat map was generated.

Based on the real-time data and intelligent operation suggestions provided by the system, the operator slowly increased the elevation angle of the crane boom to 42°. Leveraging the system’s built-in trigonometric dynamic compensation algorithm, the horizontal component force was precisely reduced. Additionally, with the assistance of the vehicle-mounted laser ranging function, the working radius was shortened by 0.5 meters. Throughout this process, the system updated parameters at a frequency of 0.1 times per second and presented the moment change curve on the windshield through customized AR projection technology. In just 12 seconds, the risk was resolved,and the load moment was brought back within the safe threshold.

Since the project’s commencement, the SeeZol Technology system has maintained stable operation, boasting a weight measurement accuracy of ±0.8% FS and an angle resolution of 0.05°. Compared with the period when traditional equipment was used, work interruptions caused by delayed overload warnings have been reduced from 3 to 4 times per month to zero, and the efficiency of each lifting operation has increased by 12%. More importantly, the system’s AI pre-diagnosis function successfully prevented three potential overload accidents, saving the project from potential direct economic losses of 1.27 million yuan. Li Gong, the chief engineer of the Zhuoyue Century Center project, commented, “SeeZol Technology’s intelligent moment system not only ensures the safety of high-risk operations but also helps us optimize 17 lifting processes through its data traceability function. It has become the’safety brain’ of super-high-rise construction.”