In the field of modern engineering construction and logistics transportation, the safety of mobile crane operations is of vital importance. Traditional load moment indicators have problems such as delayed response and insufficient data analysis capabilities. After several days of simulation and practice, SeeZol AI Innovation Lab and the company’s R&D team integrated artificial intelligence (AI) into it and realized the core application of AI in the load moment indicator of mobile cranes:

1. Real-time data intelligent analysis and processing:

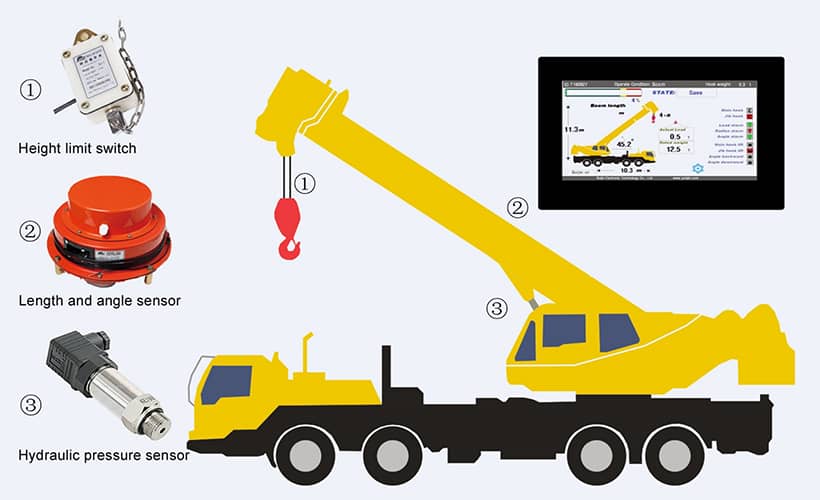

Machine learning algorithms can efficiently process multi-dimensional data such as lifting weight and boom angle collected by mobile crane sensors. Taking neural networks as an example, through deep learning of historical operation data, an accurate dynamic load moment prediction model can be constructed, which reduces the error rate by 20%-30% compared with traditional calculation methods. At the same time, AI has the ability to identify abnormal data, automatically correct erroneous data caused by sensor failure or sudden working conditions, and promptly alarm to ensure data reliability.

2. Potential risk prediction and active warning:

Based on a large amount of historical accident and normal operation data, AI uses predictive analysis technology to establish a risk prediction model. The model integrates operating parameters, equipment status and environmental factors. When it detects that the combination of boom angle and working radius is close to the accident-prone area and the load continues to increase, an orange warning will be issued in advance even if the traditional alarm threshold is not reached. In addition, AI can also predict the fatigue and failure probability of key components such as wire ropes and hydraulic cylinders based on the equipment’s service life and maintenance records, helping companies to carry out preventive maintenance and reduce accident risks.

3. Intelligent decision-making assistance and operation optimization:

Reinforcement learning algorithms enable AI to provide decision support for operators in complex scenarios. When a mobile crane needs to lift heavy objects in a small space, AI will comprehensively consider the space size, obstacle location and equipment performance parameters to plan the best crane boom extension, rotation and lifting solutions to balance safety and efficiency. At the same time, AI monitors operating behavior in real time. Once dangerous tendencies such as frequent rapid acceleration and over-range amplitude change are found, prompts and correction suggestions will be issued immediately to reduce human errors.

4. Multi-device collaborative operation management:

When multiple mobile cranes work together in large-scale projects, AI combines Internet of Things technology to build a collaborative operation management system. The system monitors the operating status, position and load data of each device in real time. When it detects an operating conflict between devices (such as overlapping slewing radius of the crane arm), the AI system will automatically coordinate the operating sequence and actions to avoid collision accidents and ensure safe and efficient construction.

Next, the SeeZol team will continue to study AI in the field of construction machinery. For example, the combination of AI algorithms and digital twin technology can realize real-time simulation and accurate risk assessment of the operation process; the deep integration of AI with 5G and the Internet of Things will promote the development of new operating modes such as smart construction sites and smart ports. With the popularization of technology and the reduction of costs, the application of AI in the field of construction machinery will be further expanded, injecting strong impetus into the industry’s safety upgrade and efficiency improvement.