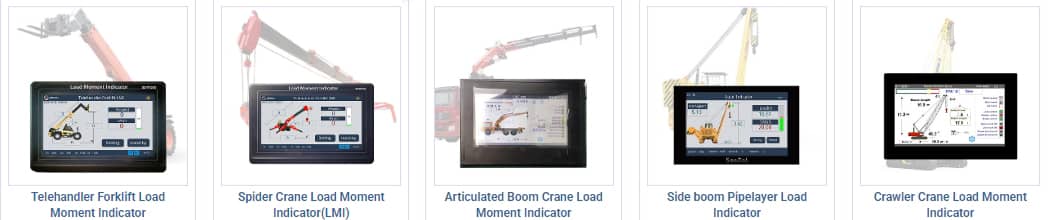

SEEZOL customizable crane load moment indicator(LMI)focuses on the differentiated needs of customers and working conditions, and can be deeply customized from four dimensions: hardware, software, function, and interaction. The following is a detailed description:

I. Hardware adaptation customization

1. Sensor selection and installation

Select sensors according to the operating scenario: strain gauge load cells for high-precision lifting; high-temperature resistant and waterproof pressure sensors for harsh environment operations. Flexible installation, tower cranes use axle pin sensors at the root of the boom to measure tension, and gantry cranes are equipped with sensors at the end of the wire rope or the outrigger to monitor weight.

2. Control and display adaptation

The control unit can adjust the size, interface and protection level as needed. Small cranes use integrated units, and the protection of harsh environment equipment reaches IP67. The display terminal provides a variety of options such as color touch screens and high-brightness LED screens, and supports customization of night vision functions.

II. Software system customization

1. Algorithms and alarm logic

Customize algorithms according to crane characteristics, optimize the torque calculation of jib cranes, and develop special amplitude compensation algorithms. Users can customize three-level alarm thresholds (85% warning, 95% second-level warning, 105% overload alarm) and corresponding actions, such as sound and light alarm, speed limit or forced shutdown.

2. Communication protocol customization

Supports multiple protocols such as Modbus and Profibus, which is convenient for integration with crane control systems and monitoring platforms. For example, smart ports transmit data through 5G, and industrial production lines and PLCs work in depth.

III. Function expansion customization

1. Industry-specific modules

Customize wind speed compensation function for wind power installation, increase radiation protection for nuclear power construction, and develop fast parameter switching function for rental cranes.

2. Standard specification adaptation

Meet domestic standards such as GB/T 28264-2020, adapt to international standards such as EU CE and US OSHA, and support internal safety process customization of enterprises.

IV. Human-computer interaction customization

1. Interface and operation optimization

Provide a multi-language interface, simplify parameter settings, support shortcut key customization and graphical operations, and lower the threshold for use.

2. Data report customization

Record basic operation data and equipment status information as needed, generate daily and weekly reports in various formats, support Excel and PDF export, and help safety management and data analysis.

Through all-round customization, the customizable crane load moment indicator has become a safety solution that meets customer needs, taking into account both operation safety and management efficiency.