Also known as Safe Load Indicators, Load Moment Indicators are indispensable safety devices that ensure the reliable operation of cranes and heavy machinery. This article explores their evolution, technical advancements, applications, and future trends in the construction industry.

1. Introduction to Load Moment Indicator (LMI/SLI)

In the construction machinery sector, Load Moment Indicators (LMIs), alternatively named Safe Load Indicators (SLIs), serve as the “safety nerve center” of lifting equipment. These systems monitor real-time load parameters (e.g., weight, boom angle, working radius) to calculate the critical load moment—a key metric to prevent crane overturning, structural damage, and operational hazards. By integrating sensing, computing, and alarming functionalities, LMIs act as 24/7 guardians for cranes, excavators, and other heavy machinery across job sites.

2. Evolution of LMI Technology: From Mechanical to Smart Systems

2.1 Early Mechanical LMIs: Limitations and Basic Functionality

In their infancy, LMIs relied on pure mechanical structures, such as spring-lever combinations or centrifugal devices. Operationally, excessive loads caused deformations in the main boom chord, which activated limit switches via amplifying rods to cut off the hoisting mechanism’s power supply. However, these mechanical systems suffered from:

- Low accuracy (errors up to ±15% or higher).

- Vulnerability to environmental factors (e.g., temperature, vibration).

- Slow response times, making them unsuitable for complex or high-risk scenarios.

2.2 Electronic Revolution: Sensors and Microprocessors

The rise of electronics marked a turning point for LMIs:

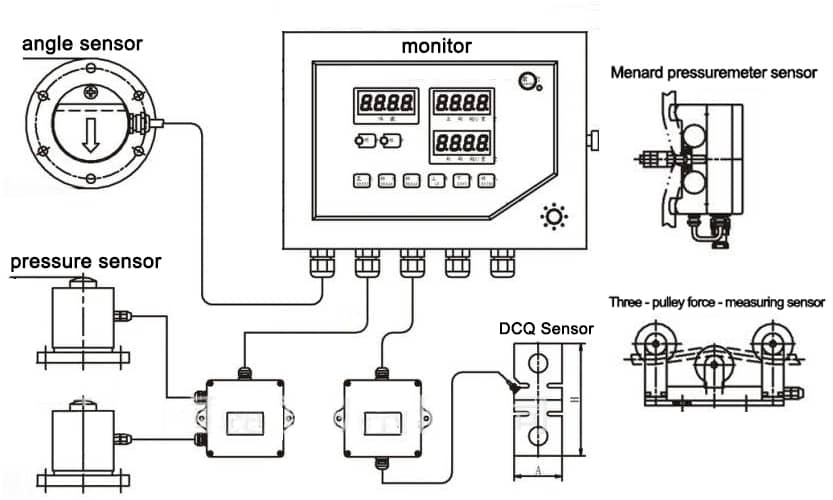

- Strain gauge sensors and microprocessors enabled real-time data collection of weight, angle, and radius.

- Calculation accuracy improved drastically to ±5%, supported by dynamic compensation algorithms that corrected moment values based on real-time boom deformations.

- New features emerged, including audible-visual alarms, motion-locking mechanisms, and digital displays, enhancing operator awareness and safety.

2.3 Modern Smart LMIs: AI, IoT, and Multi-Sensor Fusion

Today’s LMIs are at the forefront of industrial innovation:

- Multi-sensor fusion integrates inclination, wind speed, temperature, and load cell data for holistic monitoring.

- AI and edge computing power predictive analytics: built-in machine learning models can detect abnormal conditions (e.g., wire rope wear) with 99.2% accuracy and predict potential failures before they occur.

- 5G/satellite connectivity enables real-time cloud synchronization. For example, Germany’s PAT iflex5 system supports remote parameter adjustment, fault diagnosis, and fleet management, exemplifying Industry 4.0 integration.

3. Key Applications of LMIs Across Industries

LMIs are critical in sectors requiring precise load control:

| Industry | Use Case | Safety Impact |

|---|---|---|

| Construction | Tower cranes hoisting building materials in complex environments. | Prevents overturning by alarming/locking during overloads, reducing site accidents. |

| Ports & Logistics | Container cranes handling heavy cargo with high operational frequency. | Ensures efficient loading/unloading while maintaining weight-radius limits. |

| Bridge Construction | Hoisting large prefabricated bridge components. | Monitors crane balance in real time to avoid structural damage from excessive moments. |

In port operations, for instance, LMIs enable cranes to handle 20-40-ton containers with millimeter-level precision, minimizing downtime and collision risks.

4. Future Trends: AI-Driven Intelligence and Autonomous Safety

As AI and IoT technologies advance, LMIs are evolving toward:

- Autonomous decision-making: Self-adjusting systems that optimize load paths and trigger emergency stops without human intervention.

- Digital twin integration: Real-time virtual replicas of cranes and LMIs for predictive maintenance and scenario modeling.

- Cloud-based ecosystem: Centralized platforms aggregating data from multiple machines to identify industry-wide safety trends and optimize fleet management.

5. Conclusion: LMIs as Catalysts for Safer Construction

From mechanical limit switches to AI-powered smart systems, Load Moment Indicators have revolutionized crane safety. As the construction industry embraces automation and connectivity, LMIs will remain pivotal in strengthening safety defenses, reducing downtime, and driving the sector toward a more efficient, accident-free future.