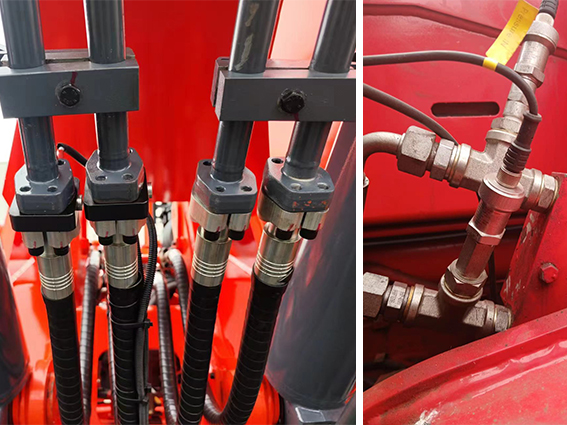

1.The pressure sensor is installed at the connection between the oil cylinder and the hydraulic oil pipe. One sensor should be installed on the oil inlet pipe and one on the oil return pipe respectively.

2.The long-angle sensor is installed on the side of the main boom of the telescopic arm.

3.The monitor is installed in the cab. We have provided the connecting components. After fixing the base, you can freely adjust the direction by using the universal joint.

4.After the hardware installation is completed, connect all the cables to the monitor and then power it on.

Set all the fixed parameters of this system to be completely consistent with the actual working state of the forklift (you can refer to the instruction manual).

Use the water tank to fill a fixed tonnage of water to complete the final setting of the forklift’s dynamic parameters.

Test the accuracy and timeliness of the system’s weight display and overload alarm respectively by changing the tonnage of the water volume.

After testing:

When the moment reaches 90% of the rated load moment, it gives loud and clear sound and light alarm signal (amber light).

When the moment reaches 100% of the rated load moment, it gives loud and clear sound and light alarm signal (red light). The alarm stops only when the torque is lower than 100% of the rated load moment.

When the moment reaches 110% of the rated load moment, it sends out overload control signal and working together with the control circuit to stop the excavator from moving towards dangerous directions (for instance, lifting, increasing radius / range). Movements toward safety directions are allowed (for instance, lowering).Working together with the control circuit of the telehandler forklift to stop upward movement but allow downward movement.

Summary: The SeeZol telehandler forklift LMI(also known as Safe Load Indicator (SLI)) has been perfectly installed and is operating well in South Africa.