Недавно компания SeeZol Technology установила 30-тонный крупномасштабный система взвешивания вилочного погрузчикаразработанная на заказ для малазийского клиента, была успешно установлена, введена в эксплуатацию и официально запущена. Благодаря высокоточным измерениям 1%, весы идеально отвечают требованиям эффективного взвешивания тяжелых грузов в местных промышленных условиях, в очередной раз демонстрируя технологическую конкурентоспособность китайского производства на зарубежном рынке.

Успешная реализация проекта началась с точной оценки потребностей. В связи с постоянным ростом производственной и складской логистики в Малайзии местным клиентам срочно потребовалось оборудование, которое могло бы объединить в себе функции обработки и взвешивания тяжелых грузов. Особенно остро ощущались ограничения традиционных вилочных погрузчиков, не имеющих функций взвешивания, и плохая адаптируемость общего весового оборудования. Используя свой многолетний опыт в исследовании и разработке промышленного весового оборудования, компания SeeZol Technology после глубокого изучения сценариев работы клиента, типов грузов и требований к точности, успешно обеспечила заказ на индивидуальную 30-тонную систему взвешивания для крупногабаритных вилочных погрузчиков.

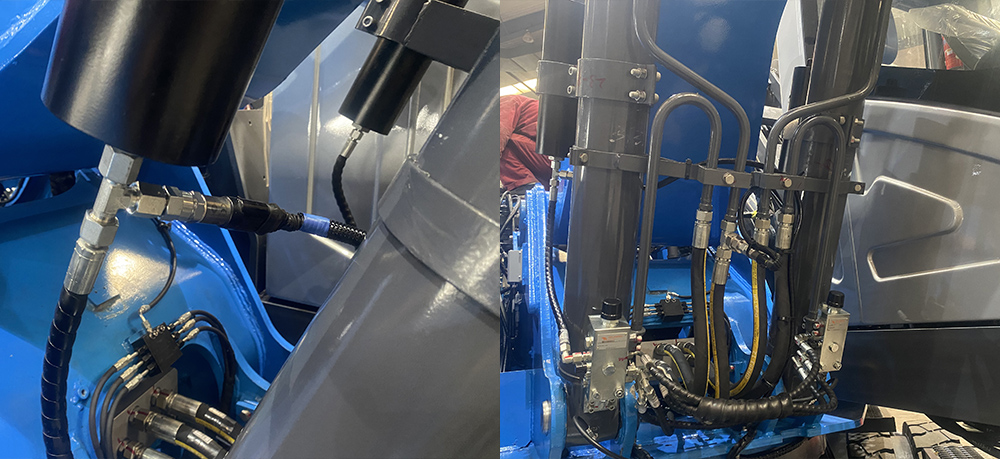

После подтверждения заказа компания SeeZol Technology собрала специальную команду R&D для начала индивидуальной разработки. Весь процесс, от выбора основного датчика и оптимизации алгоритма взвешивания до адаптации структуры оборудования, вращался вокруг 30-тонных требований к грузоподъемности и условий эксплуатации вилочного погрузчика, обеспечивая соответствие системы динамическим требованиям работы вилочного погрузчика и высокую точность взвешивания. На этапе производства соблюдались строгие стандарты контроля качества. После сборки оборудования были проведены многочисленные испытания с имитацией большой нагрузки, которые подтвердили стабильность работы системы. После этого профессиональная техническая команда отправилась в Малайзию для проведения монтажных работ на месте, преодолевая такие трудности, как различия в рабочих условиях и сложность отладки оборудования, эффективно завершив интеграцию системы, разводку проводов и калибровку параметров.

Главное отличие этой системы взвешивания 30-тонного крупногабаритного вилочного погрузчика от традиционных вилочных погрузчиков заключается в ее индивидуальной интегрированной конструкции. Не изменяя первоначальную структуру работы вилочного погрузчика, она обеспечивает интегрированную функциональность "обработка - взвешивание - запись данных". В системе используются высокоточные датчики спицевого типа и интеллектуальные весовые приборы в сочетании с эксклюзивными алгоритмами компенсации угла наклона и фильтрации вибраций, которые эффективно компенсируют такие факторы, как уклон дороги и наклон мачты во время работы, обеспечивая стабильную точность взвешивания 1%. Кроме того, система поддерживает загрузку и хранение данных в режиме реального времени, облегчая клиентам управление измерениями груза, значительно повышая эффективность работы, сокращая ошибки ручной записи и расходы на повторную обработку.

Успешная реализация этого проекта в Малайзии - это не только еще одно практическое достижение компании SeeZol Technology в области индивидуальных решений для промышленного взвешивания, но и знак того, что ее продукция и услуги достигли зрелого уровня в области поставок за рубеж. В будущем SeeZol Technology продолжит ориентироваться на потребности промышленного сектора в точных измерениях, ставя во главу угла технологические инновации, чтобы обеспечить глобальных клиентов более целенаправленными интеллектуальными решениями для взвешивания.