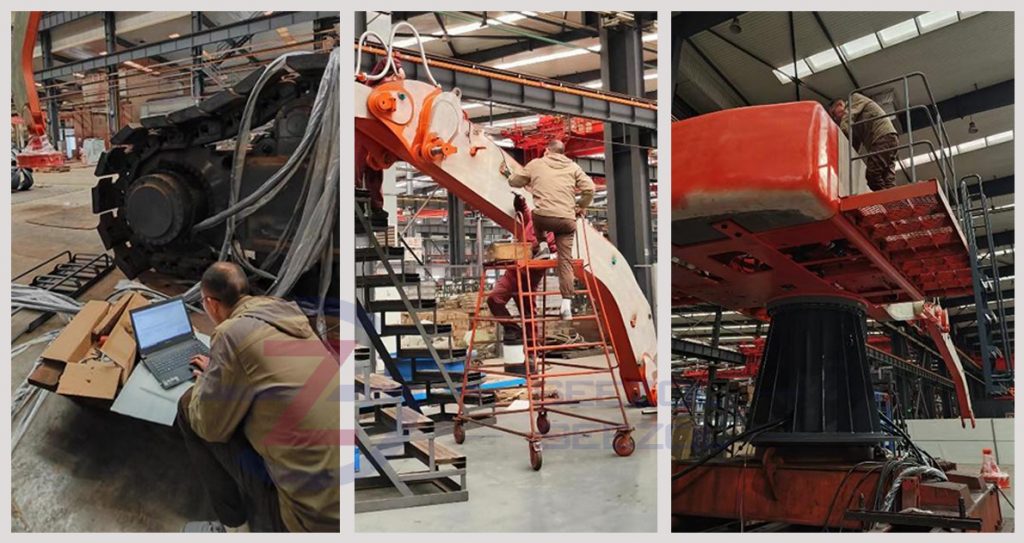

1、Installation and commissioning

The hardware installation and preliminary commissioning of the Hydraulic Material Handler are completed in the factory.

2、Hardware testing

At the construction site, check for any damage caused during transportation and connect the cables.

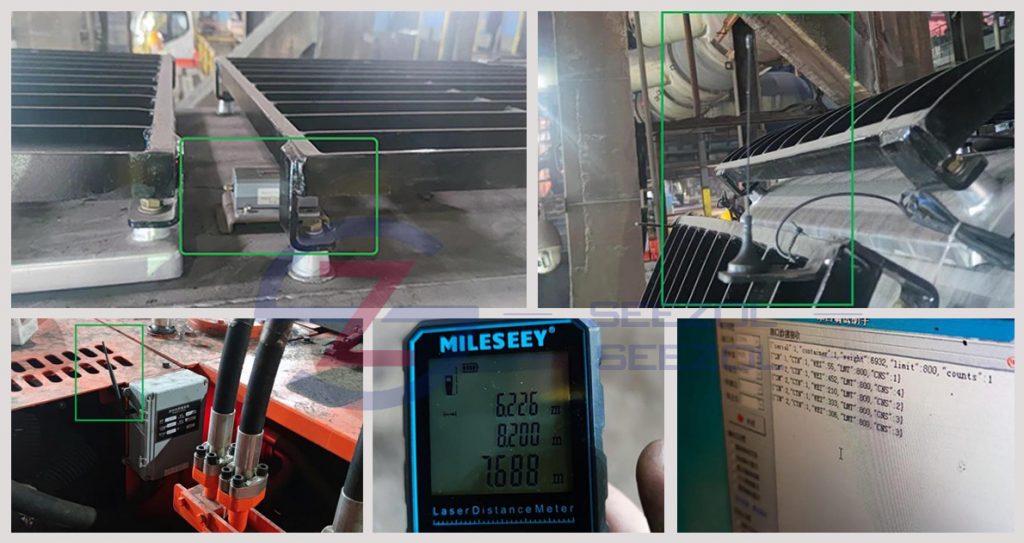

3、Communication test with the dispatching platform

Due to the limited number of ports on the collector slip ring of the Hydraulic Material Handler, we have added three additional wireless transmission modules. On – site communication with the dispatching platform adopts a wireless mode. After inspection, it can fully adapt to the harsh on – site environment with strong magnetism, high temperature, and strong interference.

The pictures above show the transmitting end of the wireless module, the receiving end of the wireless module, the transmission distance test, and the data reception test of the Pinggang dispatching platform respectively.

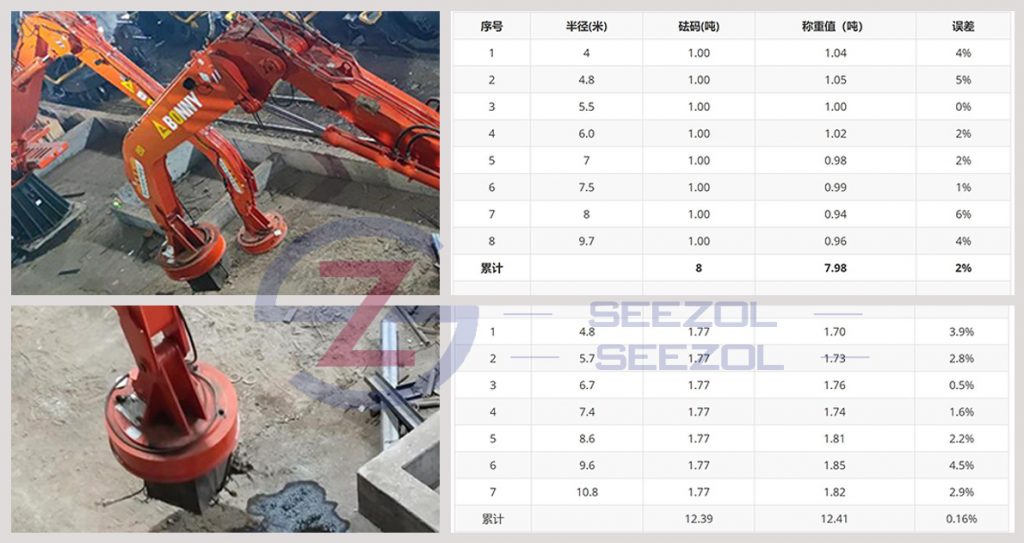

4、Weighing accuracy test

On – site tests were carried out using a 1 – ton weight and a 1.77 – ton scrap steel block at different working radii. The overall results were quite good. The weighing performance was better at the middle position (when the included angle between the arm and the boom was between 90° and 110°), with an error accuracy of 1% – 2%. The accuracy was relatively poor near the cab, generally around 5% – 6%.

5、On – site training

After completing the on – site commissioning, training will be provided for the equipment department managers, the metrology department staff, and the actual operators of the users.