Focusing on the special requirements of forklift operation scenarios, combining technical feasibility and economic returns, this report provides a feasible optimization path for the upgrade of logistics equipment.

I. Optimization Plan

1. Hardware Upgrade

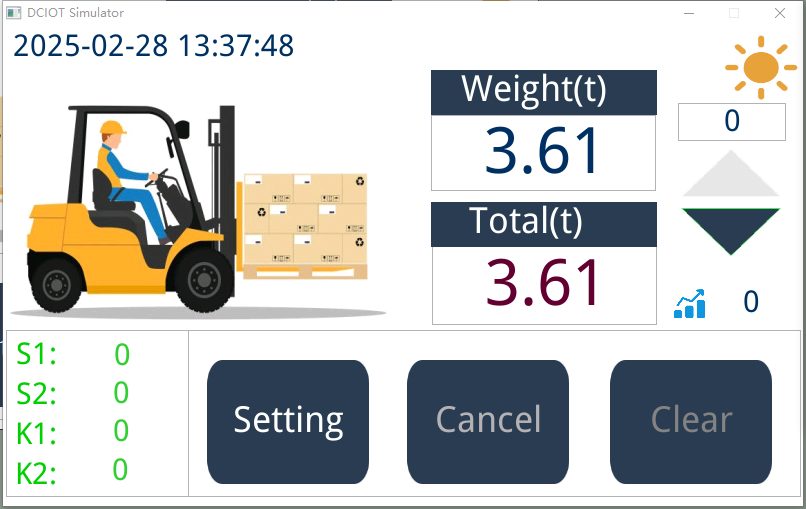

Multi-sensor Fusion Design: High-precision strain gauges (±0.5% accuracy) + hydraulic pressure sensors (monitoring lifting force). The protection level of sensors is increased to IP68, suitable for extreme environments from -30°C to 70°C.

2. Algorithm Optimization

Dynamic Compensation Algorithm: Adaptive Kalman filter is adopted, integrating acceleration, and the dynamic error is compressed to within ±3%.

3. Expansion of Intelligent Functions

Data Interconnection: Integrated Bluetooth/Wi-Fi module, and weighing data is synchronously transmitted to the WMS or on-board terminal in real-time to generate electronic waybills.

Human-computer Interaction Optimization: 4.3-inch anti-glare touch screen, with the option to upgrade to voice broadcast.

II. Verification of Implementation Effects

| Indicator | Before Optimization | After Optimization |

| Dynamic Weighing Error | ±12% | ±2.5% |

| Failure Rate | 18 times/year | ≤3 times/year |

| Data Synchronization Delay | No real-time transmission | < 1 second |

User Feedback

Logistics enterprises: The overloading rate has decreased by 70%, and the loading and unloading efficiency has increased by 20%.

Maintenance department: The modular design has reduced the maintenance time by 50%.

III. Economic Analysis

Reconstruction cost: Approximately $1200.00 per unit (including hardware, algorithm license, and installation).

Benefit calculation:

Reduction in cargo damage and equipment maintenance: Annual savings of approximately $1800.00 per unit.

Value of efficiency improvement: The annual handling capacity of each unit has increased by 15%, with a revenue of approximately $2500.00.

Payback period: Approximately 6 – 8 months.

IV. Future Plans

AI Intelligent Learning: Automatically optimize the lifting path according to the cargo distribution to reduce the risk of center of gravity offset.

Lightweight Design: Develop a low-cost version suitable for small electric forklifts (target cost ≤ $700.00).

Carbon Neutrality Adaptation: Explore solar power supply modules to meet the needs of green warehousing.

Conclusion: Through multi-sensor fusion, dynamic algorithm compensation, and intelligent upgrades, the forklift weighing system can significantly improve accuracy and practicality, helping the logistics industry to reduce costs and increase efficiency.