Aspecto técnico

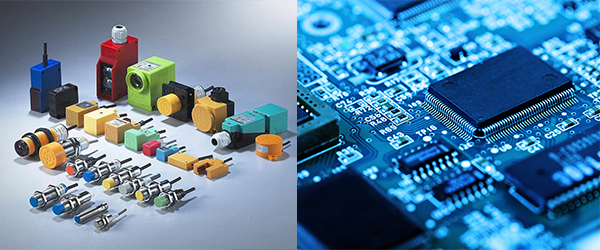

Fusión multisensor: Se adoptan sensores de ángulo, sensores de presión de aceite, etc. para obtener datos como el ángulo de la pluma y la presión hidráulica, lo que permite un cálculo preciso del par de carga.

Actualización del control inteligente: Se utilizan algoritmos de control difuso y redes neuronales para integrar datos de múltiples fuentes, evaluar con precisión el estado de trabajo y lograr un control preciso y en tiempo real.

Procesamiento mejorado de datos: Se recopila una gran cantidad de datos en tiempo real. Mediante su análisis, se puede determinar la sobrecarga y advertir sobre posibles riesgos, facilitando así la operación y el mantenimiento.

Aspecto del producto

Tipos diversos y complementarios: El tipo mecánico es simple, confiable y tiene bajo costo pero poca precisión; el tipo electrónico tiene alta precisión y respuesta rápida; el tipo hidráulico tiene gran torque y es adecuado para excavadoras grandes de trabajo pesado.

Expansión de función continua: Además de las funciones básicas de limitación de torque y alarma de sobrecarga, puede mostrar el estado de trabajo, tiene una función de diagnóstico de fallas y admite monitoreo remoto.

Tendencias de desarrollo

Inteligenteización: Combine inteligencia artificial y tecnologías de big data para lograr un control inteligente y la optimización del limitador de par de carga.

Integración: Integre el limitador de par de carga con otros sistemas de seguridad (como sistemas anticolisión, sistemas de monitoreo remoto, etc.) para formar una solución de seguridad integral.

Habilitado para IoT: Las empresas poseen sus propios sistemas de IoT personalizados y realizan personalizaciones de funciones según las necesidades de su propia industria.

Ligero y miniaturización: Mediante nuevos materiales y nuevos procesos, reducir el peso y el volumen del indicador de momento de carga para mejorar su aplicabilidad.