Fault Analysis and Handling

Sensor Fault

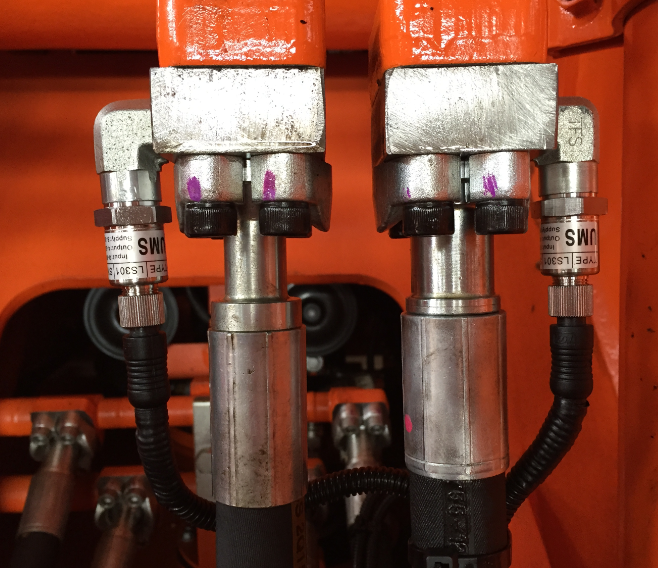

The Load Limiter depends on pressure and angle sensors. When they malfunction, the Load Moment Indicator may misjudge the load. Use standard tools to calibrate. Replace damaged sensors.

Circuit Fault

In an LMI Crane, circuit issues like open or short circuits can disrupt the Safe Load Indicator (SLI). This leads to wrong load readings or function loss. Inspect circuits, repair breaks, and replace damaged cables.

Controller Fault

A faulty controller in the Load Limiter can cause chaos. In an LMI Crane, it may result in erratic movements. In the SLI, it can give inaccurate warnings. Fix hardware problems by replacing components and update software for bugs.

Display Fault

A damaged display in the Load Limiter can hide load data. In an LMI Crane, data errors mislead operators. For the SLI, an unclear display is dangerous. Replace a broken screen and fix root – cause issues.

Preventive Measures

1.Clean and inspect Load Limiter sensors monthly. Calibrate and test them quarterly. Protect the crane from impacts.

2.Check LMI Crane circuits weekly. Replace weak cables every six months. Install protection and dehumidifiers for the SLI.

3.Equip the Load Moment Indicator’s controller with a cooler. Update software quarterly. Keep the crane away from strong magnets.

4.Put a guard on the SLI display. Do monthly self – checks. After repairs, simulate work to test the Load Moment Indicator.