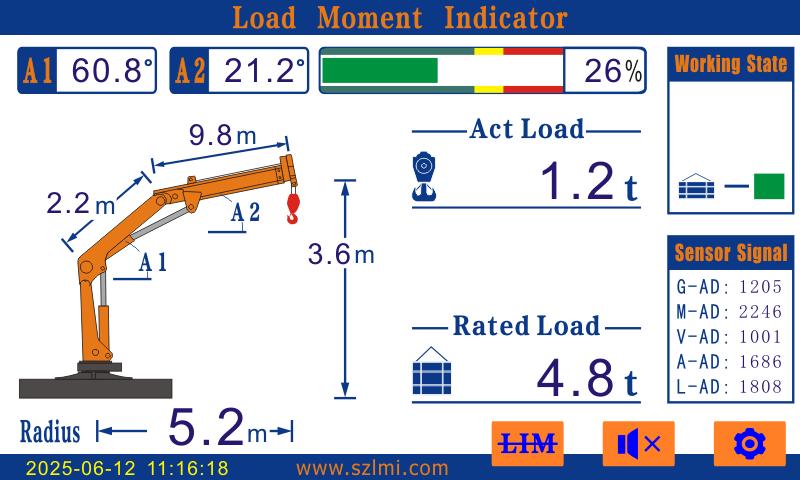

SEEZOL индикатор грузового момента (ИГМ) для кранов с шарнирно-сочлененной стрелой Система контролирует такие параметры, как нагрузка, длина стрелы и угол наклона, в режиме реального времени, точно рассчитывая фактический грузовой момент и сравнивая его с номинальными значениями. Система обеспечивает многоуровневые звуковые и визуальные предупреждения для индикации рисков, автоматически отключает опасные движения при превышении пределов и реализует предохранительные блокировки. Оснащенная дисплеем, система является ключевым устройством безопасности, предотвращающим перегрузку и опрокидывание.

Этот индикатор грузового момента прост в установке и имеет степень защиты IP65, эффективно выдерживая типичные воздействия окружающей среды. Однако, из-за сложных внешних условий или вмешательства человека, возможны сбои в работе системы. Распространенные неисправности Индикатор грузового момента шарнирно-сочлененного крана (LMI) Часто связаны с датчиками, проводкой или контроллерами. Для облегчения самостоятельной диагностики ниже перечислены распространённые нетехнические неисправности и способы их устранения, которые помогут быстро восстановить работу оборудования, сократить время ремонта и повысить эффективность работы.

- Ненормальное отображение

1. Неточное отображение нагрузки

Причина: дрейф нулевой точки датчика, поверхностный нефтепродукт, неплотная проводка или неправильная калибровка.

Решение: Очистите датчик спиртом; затяните клеммную колодку; войдите в режим калибровки и выполните калибровку нуля. Если отклонение велико, выполните калибровку полной шкалы с помощью эталонного груза.

2. Никаких изменений или скачков в длине/угле руки.

Причина: застрял датчик длины рычага, изношен датчик угла поворота, пережата или оборвана проводка.

Решение: Очистите датчик и добавьте смазку; используйте мультиметр для проверки сигнала датчика угла поворота; замените его, если он ненормальный; проверьте проводку на наличие повреждений и переподключите или замените ее.

3. Наклон в горизонтальной плоскости (фактически выровнен)

Причина: Датчик прижат посторонними предметами, неплотно закреплен или имеет внутренние повреждения.

Решение: Удалите посторонние предметы со дна; затяните крепежные винты; замените датчик после подтверждения повреждения.

- Сбой функции тревоги

1. Без предупреждения

Причина: Поврежденный зуммер/индикатор, неправильные настройки порога или неисправность программы.

Решение: Замените компонент сигнализации; сбросьте пороговое значение до заводского значения (80% от номинального крутящего момента); если перезапуск контроллера не помог, обратитесь к производителю для обновления программы.

2. Отсутствие блокировки после превышения предела

Причина: неисправность реле, короткое замыкание или прерывание связи.

Решение: Проверьте состояние питания реле и замените его, если оно повреждено; удалите все недопустимые замыкания; используйте диагностический инструмент для проверки связи между контроллером и гидравлическим клапаном; и отремонтируйте интерфейсный или коммуникационный кабель.

- Сбой при включении питания

Черный экран

Причина: сбой питания, повреждение дисплея или неисправность модуля питания.

Решение: Проверьте напряжение питания и замените перегоревший предохранитель; проверьте внешний резервный дисплей и замените его, если он поврежден; отремонтируйте или замените модуль питания контроллера.

- Другие неудачи

1. Размытый/мерцающий дисплей: протрите поверхность и заново подключите модуль подсветки.

2. Внезапный сброс данных: замените резервную батарею; если сброс происходит часто, замените микросхему памяти.

- Меры предосторожности при обращении

· Перед устранением неисправностей опустите подвешенный объект на землю и отключите питание, чтобы избежать неправильной работы.

· Не допускайте короткого замыкания в цепи блокировки. В случае сложных проблем обратитесь к специалисту.

· Регулярное техническое обслуживание может снизить количество неисправностей. Повторные неисправности требуют проверки оборудования на наличие механических повреждений.