I. Project Overview

This project involved SeeZolTechnology custom-designing an safety monitoring system(also known as indicador de momento de carga or safe load indicator) for Bonny Heavy Machinery’s 22-ton hydraulic material. In mid-November, the entire installation and commissioning process for multiple material handling machines was completed in just three days. The system aims to help Bonny Heavy Machinery improve the operating efficiency of its material handling machines, reduce the risk of malfunctions, and provide data support for refined equipment management by monitoring key operating parameters in real time. It has now successfully passed joint acceptance by both parties and is officially in use.

II. Core Installation and Configuration

The system focuses on the core operating dimensions of the material handler, ensuring precise installation and adaptation of key components:

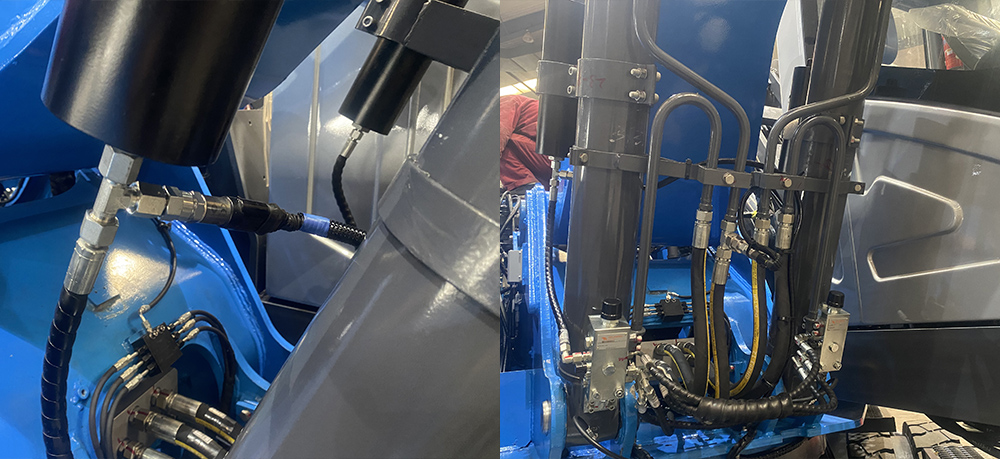

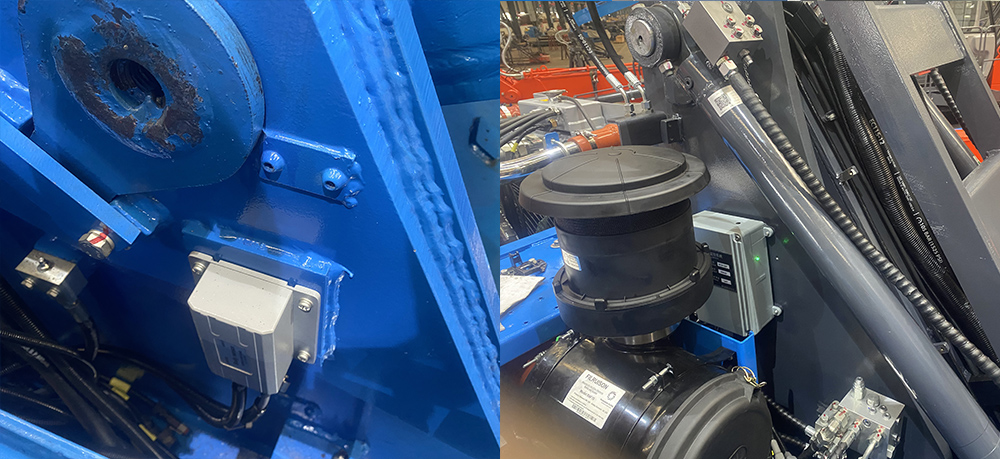

- Angle Sensing System: Precisely deployed angle sensors on the bucket arm, boom, and chassis capture real-time equipment operating posture data, providing a basis for precise motion control. The installation location avoids motion interference, ensuring strong stability.

- Oil Pressure Monitoring Module: Oil pressure sensors are installed at key points in the hydraulic system’s oil inlet and return lines, providing comprehensive monitoring of hydraulic system pressure changes and ensuring safe operation of the hydraulic system.

- Core Control Unit: The monitoring host is installed in a convenient maintenance area on the chassis, integrating data acquisition, processing, and storage functions. The wiring is standardized and orderly, and features wear-resistant and waterproof protection, adapting to the complex operating environment of the material handler.

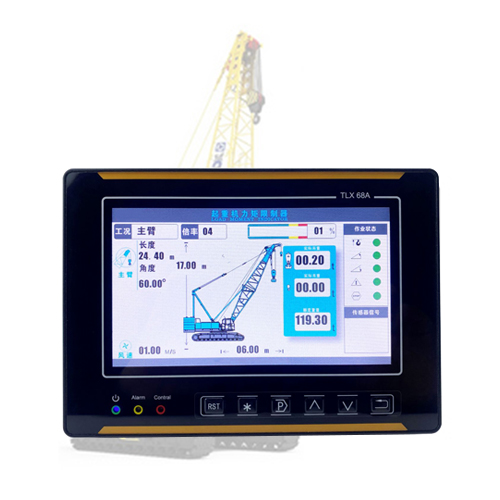

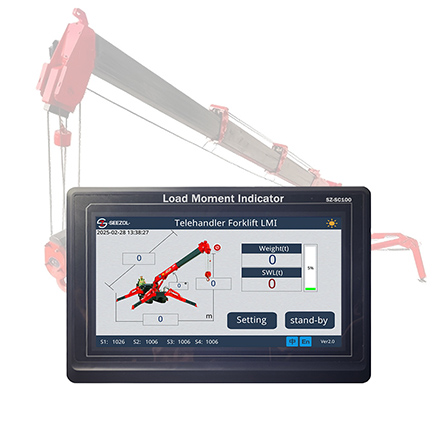

- Cab Terminal: The display is installed in a user-friendly area of the cab, offering convenient operation and intuitively displaying various operating data, allowing the driver to monitor the equipment status in real time.

III. Debugging and Acceptance Highlights

After installation, the system performance was verified through full-scale testing: sensor data acquisition was accurate, and angle and oil pressure measurement errors were controlled within the industry’s excellent range; data transmission between the monitoring host and the display was real-time and stable, without delays or lag. Joint acceptance by both parties confirmed that the system installation was standardized, its operation was reliable, and it fully met the monitoring requirements for the grab crane operation, achieving the preset results.

IV. Core Values of the System

- Improved Efficiency: Real-time monitoring of bucket and boom angles and hydraulic pressure helps optimize work processes, reduce unnecessary movements, and improve material handling efficiency.

- Enhanced Safety: Dynamically captures risk signals such as abnormal hydraulic system pressure and vehicle posture deviations, providing early warnings of equipment malfunctions and reducing operational safety hazards.

- Empowered Management: The system stores historical operating data, providing data support for equipment maintenance and performance optimization, enabling refined management and extending equipment lifespan.

- Strong Adaptability: The installation process does not affect the original structure of the material handler, is compatible with Bonny Heavy Machinery’s 22-ton class material handlers, offers convenient maintenance, and provides outstanding cost-effectiveness.

V. Conclusion

The SeeZol Technology 22-ton hydraulic material handler safety monitoring system, with its precise monitoring capabilities and stable performance, injects technological power into Bonny Heavy Machinery’s material handling operations. The system not only addresses the pain points of traditional operations, such as difficulty in controlling equipment status and reliance on experience for maintenance, but also promotes a dual improvement in operational efficiency and safety through data-driven methods. It is an excellent solution for the intelligent upgrading of heavy machinery equipment. In the future, SeeZol Technology will continue to provide technical support to help Bonny Heavy Machinery achieve higher quality production operations.