من خلال التركيز على المتطلبات الخاصة لسيناريوهات تشغيل الرافعة الشوكية، والجمع بين الجدوى الفنية والعوائد الاقتصادية، يقدم هذا التقرير مسار تحسين قابل للتطبيق لترقية المعدات اللوجستية.

أولا: خطة التحسين

1. ترقية الأجهزة

تصميم دمج متعدد المستشعرات: مقاييس انفعال عالية الدقة (دقة ±0.5%) + مستشعرات ضغط هيدروليكية (لرصد قوة الرفع). مستوى حماية المستشعرات مُحسّن إلى IP68، وهو مناسب للبيئات القاسية من -30 درجة مئوية إلى 70 درجة مئوية.

2. تحسين الخوارزمية

خوارزمية التعويض الديناميكي: تم اعتماد مرشح كالمان التكيفي، ودمج التسارع، وتم ضغط الخطأ الديناميكي إلى ±3%.

3. توسيع الوظائف الذكية

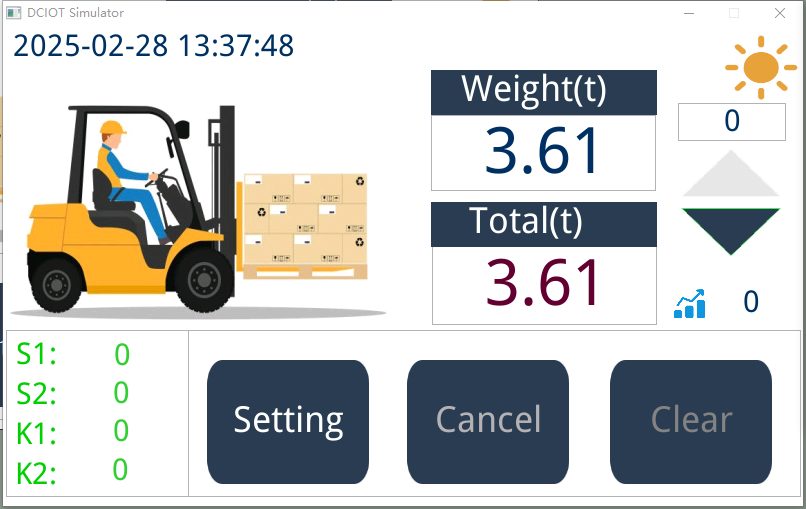

ربط البيانات: وحدة بلوتوث/واي فاي متكاملة، ويتم نقل بيانات الوزن بشكل متزامن إلى نظام إدارة المستودعات أو المحطة الطرفية الموجودة على متن السفينة في الوقت الفعلي لإنشاء سندات الشحن الإلكترونية.

تحسين التفاعل بين الإنسان والحاسوب: شاشة تعمل باللمس مضادة للتوهج مقاس 4.3 بوصة، مع خيار الترقية إلى البث الصوتي.

ثانياً. التحقق من تأثيرات التنفيذ

| مؤشر | قبل التحسين | بعد التحسين |

| خطأ الوزن الديناميكي | ± 12% | ± 2.5% |

| معدل الفشل | 18 مرة/سنة | ≤3 مرات/سنة |

| تأخير مزامنة البيانات | لا يوجد نقل في الوقت الحقيقي | < 1 ثانية |

تعليقات المستخدم

مؤسسات الخدمات اللوجستية: انخفض معدل التحميل الزائد بنسبة 70%، وزادت كفاءة التحميل والتفريغ بنسبة 20%.

قسم الصيانة: التصميم المعياري يقلل من وقت الصيانة بنسبة 50%.

ثالثاً. التحليل الاقتصادي

تكلفة إعادة البناء: حوالي 1200.00 دولار أمريكي لكل وحدة (بما في ذلك الأجهزة، وترخيص الخوارزمية، والتثبيت).

حساب الفائدة:

تقليل أضرار الشحنات وصيانة المعدات: توفير سنوي يبلغ حوالي 1800 دولار أمريكي لكل وحدة.

Value of efficiency improvement: The annual handling capacity of each unit has increased by 15%, with a revenue of approximately $2500.00.

فترة الاسترداد: حوالي 6 – 8 أشهر.

رابعاً. الخطط المستقبلية

التعلم الذكي بالذكاء الاصطناعي: تحسين مسار الرفع تلقائيًا وفقًا لتوزيع البضائع لتقليل خطر إزاحة مركز الثقل.

تصميم خفيف الوزن: تطوير نسخة منخفضة التكلفة مناسبة للرافعات الشوكية الكهربائية الصغيرة (التكلفة المستهدفة ≤ 700.00 دولار).

التكيف مع الحياد الكربوني: استكشاف وحدات إمداد الطاقة الشمسية لتلبية احتياجات التخزين الأخضر.

خاتمة:من خلال دمج أجهزة الاستشعار المتعددة، وتعويض الخوارزمية الديناميكية، والترقيات الذكية، يمكن لنظام وزن الرافعة الشوكية تحسين الدقة والعملية بشكل كبير، مما يساعد صناعة الخدمات اللوجستية على خفض التكاليف وزيادة الكفاءة.